The SAIW is continuously looking to provide the market with courses that are pertinent to the ever-changing conditions in the welding industry. The following two courses answer specific needs confronting our industry at the present moment.

Piping Inspectors Course

This new Piping Inspectors course is based on certification requirements similar to the Competent Person and Inspector of Pressurised Equipment, consisting of a one week theoretical course, followed by an examination. The candidate is then required to gather experience as a pipeline inspector prior to application for certification. It is also a requirement for the inspector to have comprehensive knowledge of the South African legislation for Pressure Equipment, therefore it is a pre-requisite for the student to have successfully undertaken a Legal Knowledge course on the PER and SANS 347.

Successful candidates will have comprehensive knowledge on the requirements of International Pipeline and Piping Component Among others, the following International standards will be covered API 570, API 571, API 574, API 576, API 579, and ASME B31.3 and ASME B16.5 construction standards. |

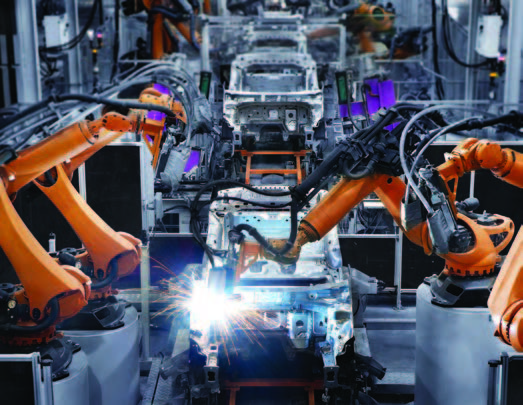

International Robotic WelderThe International Robotic Welder training course is designed to give the candidate the necessary theoretical knowledge on welding technology by equipping him/her with the skills to manage all aspects of a robotic welding operation including design of the welding task, safety and troubleshooting of the welding operation. |

|

|

|

|

The course gives the candidate an understanding of the following aspects of Robotic Welding (RW):

The training includes a practical module which will teach the Welding Operator

|

|

|

|